Stock and bill of material tracking (BOM) with Micro ERP

We create the BOMs necessary for the production of our customer orders in the Micro ERP system.

This system controls production process automatically. It helps us to manage Production process even more effectively.

Warehouse entrance and exit monitoring

All products coming to our production area are pre-checked by comparing product BOMs and delivery note during acceptance of goods.

After acceptance of the goods, the Incoming Quality Control (IQC) process starts. We perform technical control to determine the suitability of incoming products for production process.

The products that successfully passed Incoming Quality Control are ready to be stocked in Warehouse. Then we quarantine products that are not suitable for production. In this way, we can prevent products that don”t meet standard requirements from interfering to the production process.

Air conditioning and monitoring

There are sensors that measure humidity and temperature at every point of our production area. We record data from these sensors 24/7. Since we store these data digitally, we can easily perform retrospective analysis. If indicators show that measuments are going out of parameters, then person in charge is immediately notifiyed by e-mail and SMS.

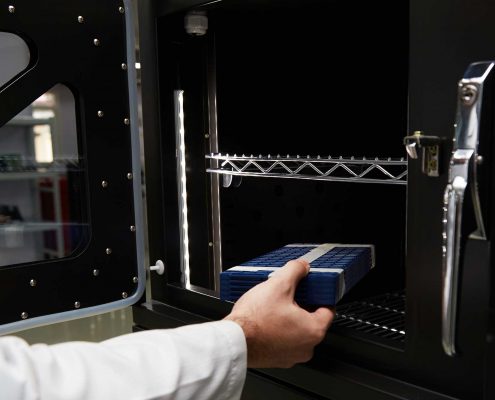

Private Customer Warehouse

We provide special locked and controlled storage areas to our customers for the products we use in continuously production. By making continuous production, we prevent the breaking of the product supply chain, which is very important for our customers.

ESD coating and ESD protected product shelves

We use ESD floor coating and ESD product shelves in our production and storage areas to prevent electronic products from being affected by static electricity